Swirltex’s BEMF Wastewater Treatment Technology Recognized As The Top New Water Technology by Water Canada

29 August 2024

Achieving ESG Excellence With Sustainable Wastewater Treatment

18 March 2025Swirltex Technology Vs DAF Systems

Does your food and beverage processing facility still rely on outdated wastewater systems like DAF (Dissolved Air Flotation)? These systems may have worked in the past, but they are no match for today’s challenges. High energy costs, frequent maintenance, and poor performance with modern contaminants can leave your operations struggling to keep up.

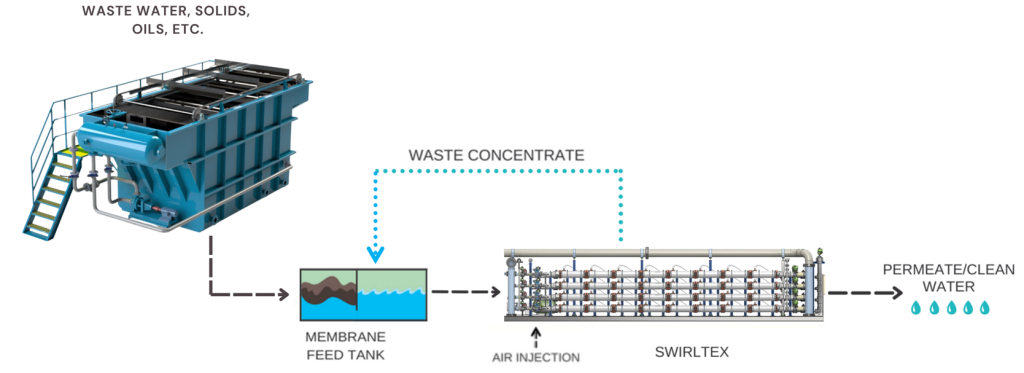

That’s where Swirltex’s Buoyancy-Enhanced Membrane Filtration System comes in – a solution designed to retrofit your existing setup, making it more efficient, sustainable, and cost-effective.

Why Swirltex Is Better Than DAF Systems

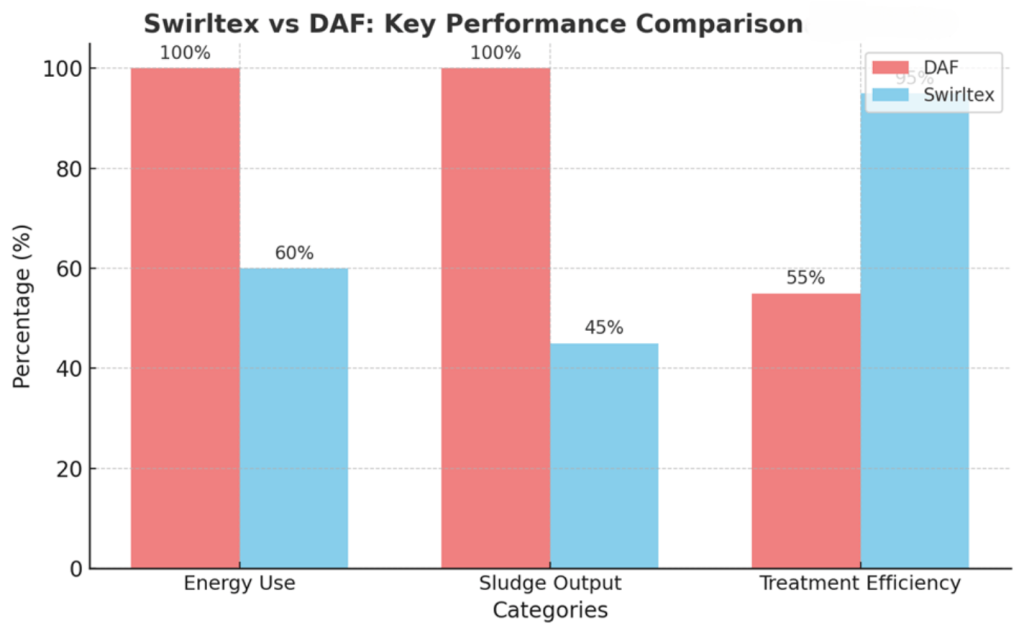

Let’s face it: DAF systems are energy hogs and often create more problems than they solve. Swirltex takes a different approach:

- Lower Costs: Swirltex uses 40% less energy than DAF systems, meaning lower utility bills.

- Cleaner Results: While DAF struggles with high fats, oils, and grease (FOG), Swirltex removes 95% of FOG, bacteria, suspended solids and other contaminants with ease.

- Less Waste: DAF generates large amounts of sludge, but Swirltex produces 55% less with options for sludge dewatering, cutting disposal costs significantly.

Swirltex Retrofits – Fast, Affordable, and Sustainable

The Swirltex system design is modular, compact and very effective. Retrofitting with Swirltex is quick – most installations are complete in 6-8 weeks. It’s also budget-friendly, saving factories up to 50% on upfront costs compared to building a new system.

But the real magic is in sustainability. Swirltex allows food and beverage factories to reuse up to 60% of treated water for specific purposes, which is great for the planet and company image. Imagine cutting your water bills by 25% every year!

Time to Make the Switch

Swirltex BEMF technology is a smarter way to manage wastewater. You will save money, reduce waste, and contribute to a more sustainable future for your business.

Stop letting outdated systems hold you back. Retrofit with Swirltex today and see the difference for yourself.

Contact us today to help you reduce your wastewater surcharges.