FOOD & BEVERAGE WASTEWATER TREATMENT

DAIRY WASTEWATER CASE STUDY

CLIENT SPECIFICATIONS

Prior to implementing our system, the Client faced:

- extremely high disposal costs for each of its 15 facilities across Canada;

- a highly contaminated waste stream that was high in TSS, COD, and BOD from the dairy production process; and

- an inadequate waste system that produced low-quality permeate.

PROJECT GOALS

For this client, the ideal solution required:

- ultrafiltration technology to allow treated dairy wastewater to be re-used or safely discharged;

- a minimum flux rate of 100LMH; and

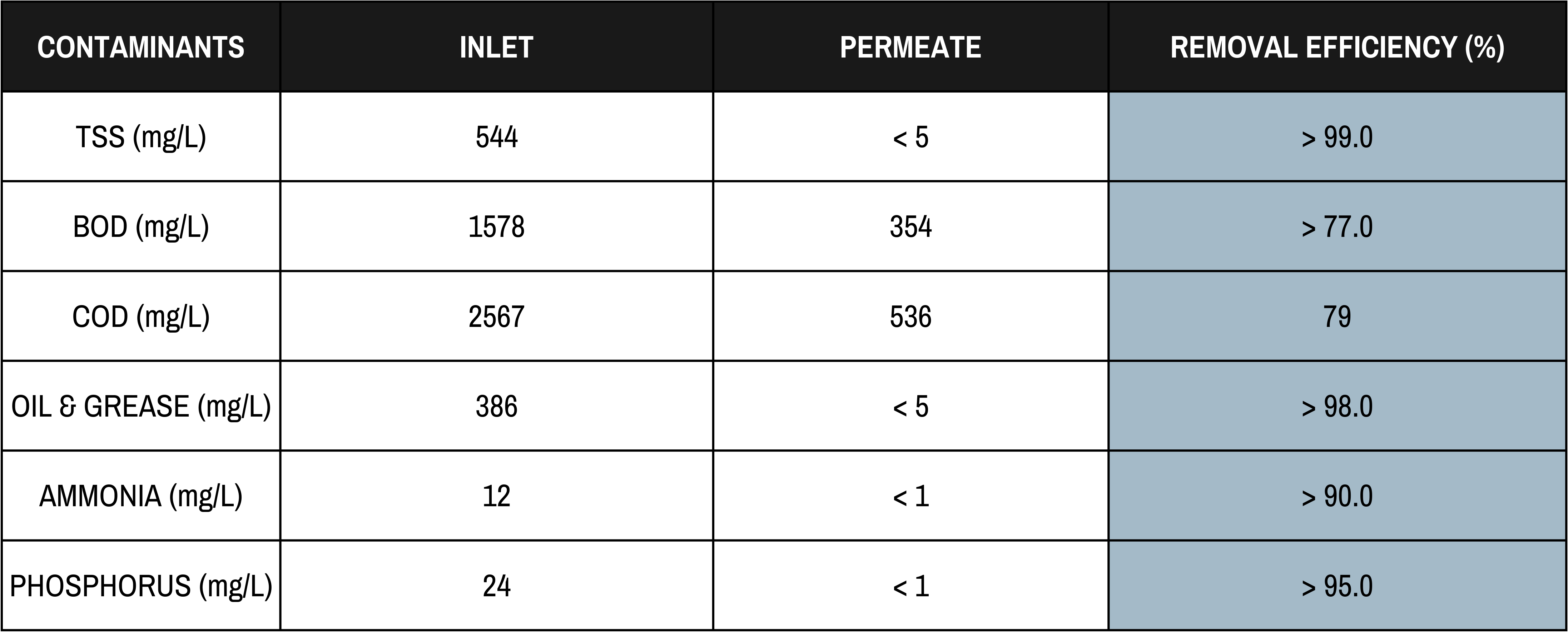

- effective removal of key contaminants and surcharge savings for the following: TSS < 50mg/L, BOD < 300 mg/L, COD < 600 mg/L, and fats, oils, and grease (FOG) < 50 mg/L.

PROJECT SUCCESS

For preliminary testing, Swirltex collected a composite sample from the Client’s facility. After successful chemical pre-treatment, the wastewater was pumped into the Swirltex system for its final treatment. Both the untreated wastewater and permeate were sent to a third-party laboratory to verify the accuracy of test results.

Typically, the Food & Beverage industry struggles to filter wastewater that is highly contaminated with organic compounds. However, Swirltex’s system demonstrated exemplary removal efficiency for key contaminants at the specified flux rate. Additionally, Swirltex’s treatment generated significant surcharge savings for the parameters of interest, resulting in overall lower operational expenditures. For this Client, Swirltex provided:

- an opportunity for the Client to meet ESG commitments by making wastewater re-usable;

- a cost-effective solution that generates long-term operational savings; and

- reliable technology applicable for drink production and manufacturing as well as food production and packaging.