INDUSTRIAL WASTEWATER

COAL TERMINAL CASE STUDY

CLIENT SPECIFICATIONS

This client has a major coal terminal with extremely challenging industrial wastewater. Prior to implementing the Swirltex system, the Client faced:

- Excessive water consumption for dust control – using enough daily to support the water needs of a small town;

- Limited options for filtration systems that can effectively handle fine coal particles;

- An existing filtration system that was prone to membrane fouling and required on-going maintenance.

PROJECT GOALS

The client’s ideal solution required:

- effective filtration primarily for solids, and oil removal;

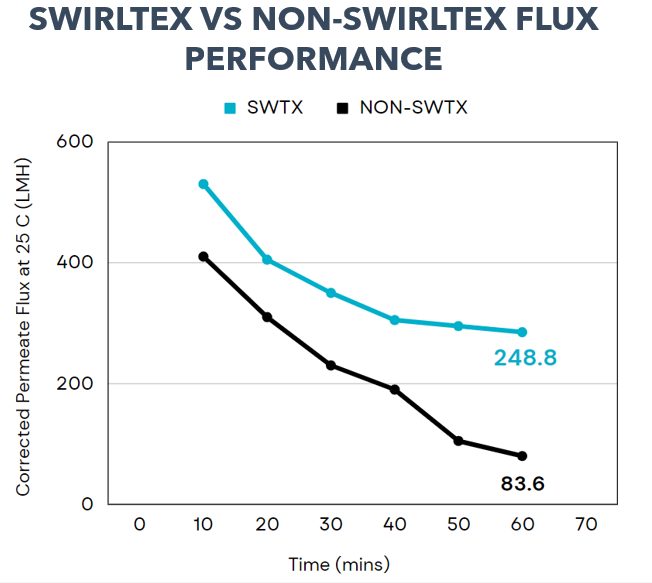

- consistent membrane permeate flux production of > 100 LMH; and

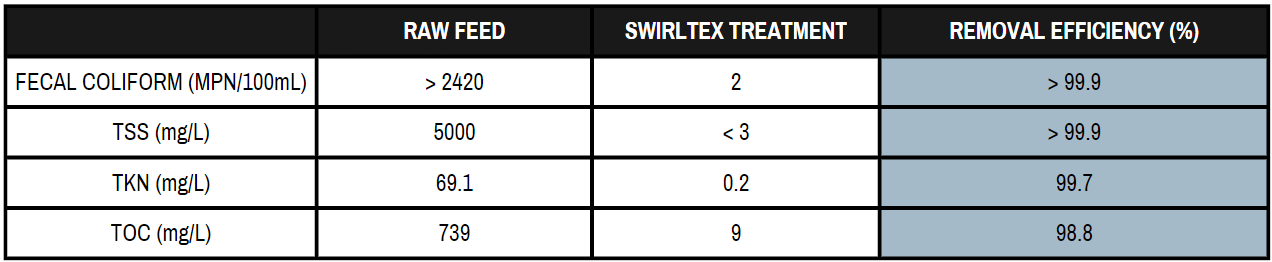

- target parameters for key contaminants such as TSS < 50 mg/L, oil and grease < 5 mg/L, iron < 10 mg/L, and bacteria < 165 pg/L.

PROJECT SUCCESS

For preliminary testing, Swirltex collected a composite sample from the Client’s facility. After successful chemical pre-treatment, the wastewater was pumped into the Swirltex system for its final treatment. Both the untreated wastewater and permeate were sent to a third-party laboratory to verify the accuracy of test results.

As a necessary practice for all coal terminals, the Client implements wet-type dust removal. This requires significant amounts of water to continuously spray down coal stores and stockpiles. As shown in the table above, Swirltex’s high removal efficiency allowed the Client to access its waste stream’s re-use potential. With our system, the treated water could be safely re-used in spray bars and other dust control mechanisms to minimize the terminal’s overall freshwater consumption. Furthermore, Swirltex’s system provided greater operational efficiency by reducing the number of membrane skids required from 3 to 1. This also provided generous savings in terms of capital expenditures and non-compliance penalties. Overall, by choosing Swirltex to handle its wastewater, the Client:

- eliminated its excessive freshwater consumption, transitioning to more sustainable water use;

- streamlined its filtration process to reduce capital expenditures and carbon emissions; and

- decreased energy consumption to make daily operations more sustainable.