FORESTRY CASE STUDY – KILN WASTEWATER TREATMENT

Client Challenges

Our client is one of North America’s leading producers of timber and lumber products. Sawmills often face challenges in efficiently managing wastewater from their operations due to high concentrations of TSS, CBOD, oil & grease and other contaminants. Traditional wastewater management methods, such as evaporators, can be energy-intensive and may not effectively manage diverse wastewater types, leading to high sludge, environmental concerns and increased operational costs.

Client Project Goals

The client, a sawmill operator, aimed to enhance its wastewater treatment processes to improve efficiency, reduce energy consumption, and increase sustainability. Key project goals include:

- Finding a solution that would enable effective reuse of dry kiln wastewater.

- Reduce energy costs, and

- Align with corporate environmental initiatives.

Project Success

Testing Procedure:

Swirltex collected a composite sample from the Client’s facility. After successful chemical pre-treatment, the wastewater was pumped into the Swirltex BEMF system for its final treatment. The untreated wastewater and permeate were sent to a third-party laboratory to verify the accuracy of test results.

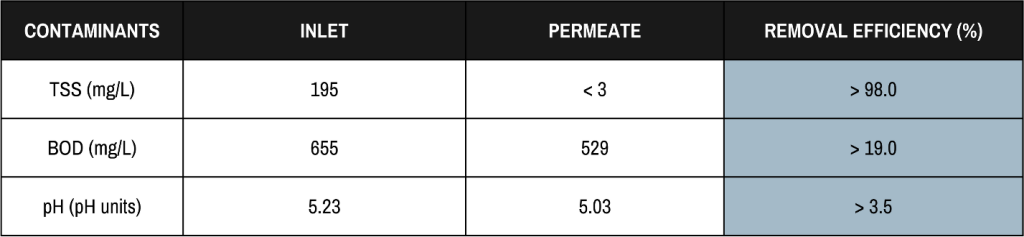

The table above shows that Swirltex’s innovative BEMF technology provided an ideal solution for the client’s challenges and goals. The sawmill achieved:

- Enhanced Wastewater Treatment and Reuse: Swirltex’s technology optimized wastewater treatment processes through a fully automated buoyancy-based membrane filtration method. This allowed for the efficient elimination of TSS and contaminants in diverse wastewater types, supporting the sawmill’s ability to reuse wastewater for beneficial purposes (e.g., saw cooling and irrigation).

- Energy Efficiency and Cost-Effectiveness: Swirltex’s system operated with approximately 90% less energy than conventional evaporators, leading to significant energy savings and reducing the sawmill’s carbon footprint.

- Improved environmental and sustainability initiatives and enhanced corporate social responsibility profile.

In summary, Swirltex’s system offered a modern and robust solution for sawmill & forestry applications, serving as an alternative to traditional evaporators. The system also enabled the efficient reuse of dry kiln wastewater, enhancing water efficiency and sustainability within the forestry industry.

Contact us today to learn more: sales@swirltex.com