Wastewater Treatment – The Swirltex Story

28 June 2022Lithium Extraction – The Mineral We Didn’t Know We Needed

14 July 2022Coal Wastewater - Tiny Particles, Huge Problem

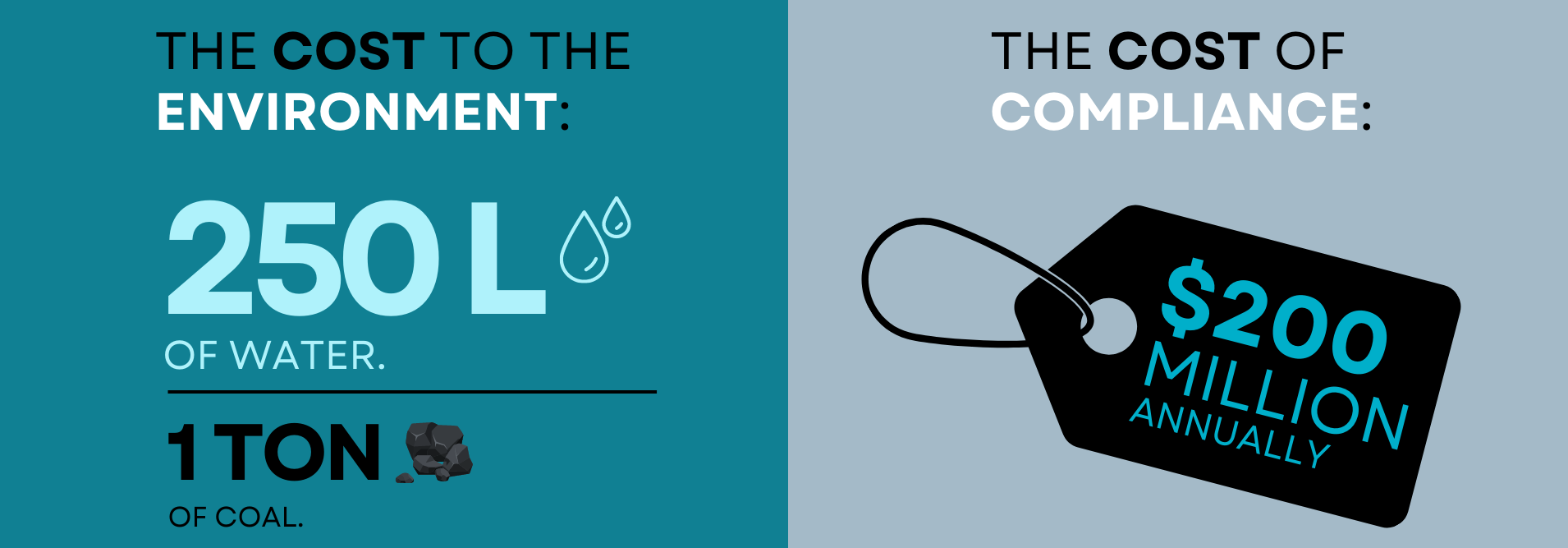

As the future of energy shifting towards renewable energy sources, coal is becoming less favorable. The industry’s decline is attributed to major environmental concerns associated with coal mining. Mining processes consume vast amounts of water—approximately 250 liters of water per one ton of coal—to prevent equipment from overheating and coal dust from catching fire. Water is essential for mining activity but coal wastewater is highly contaminated and impossible to re-use. Because the pollutants in coal wastewater are extremely fine, existing filtration systems struggle to produce high quality permeate. As a result, wastewater regulations are becoming increasingly difficult to meet. In the United States, regulatory compliance costs coal-fired plants around $200 million USD every year. It is no surprise that many coal plants are closing operations in response.

Coal mining brings environmental and regulatory challenges with it; however, coal is a crucial resource. As of 2021, the global coal mining industry is worth $790.63B USD. Moreover, coal powers 37% of the world’s electricity and is a key ingredient for steel manufacturing. Clearly, we need coal but the strain it puts on the environment cannot be ignored. What this industry needs is a solution for handling coal wastewater.

What’s In Coal Wastewater

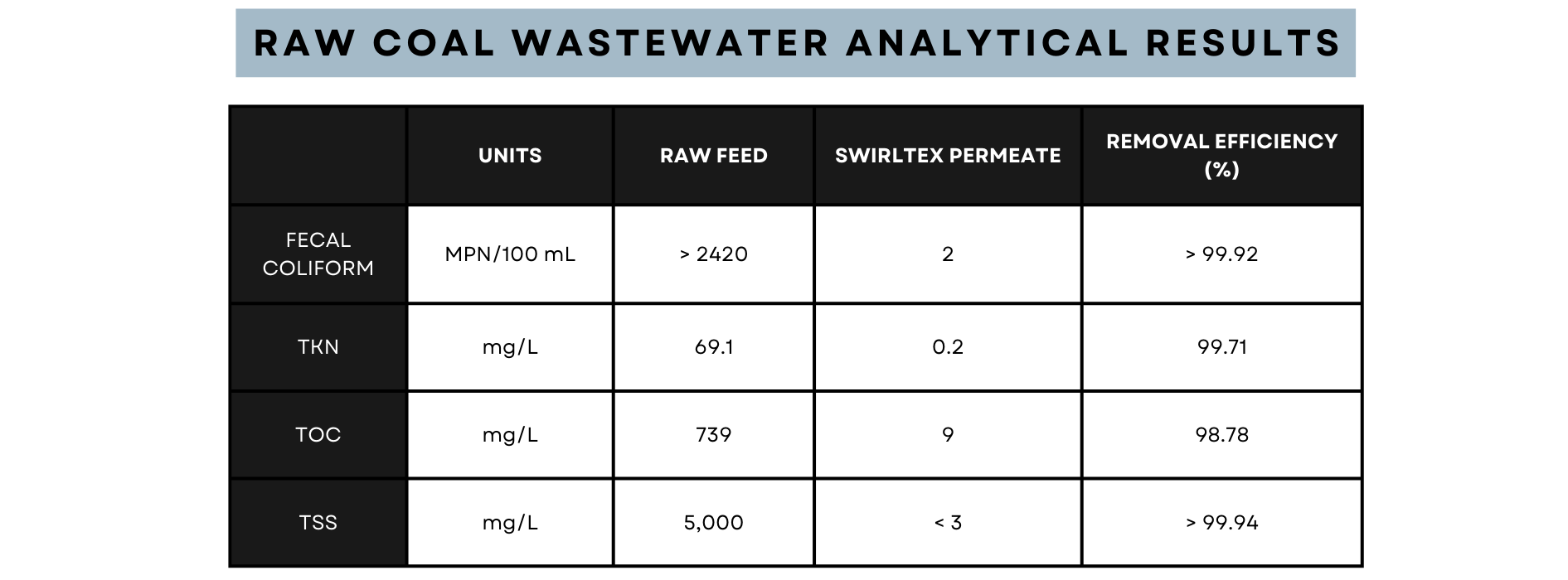

Coal wastewater is the perfect opportunity to showcase the effectiveness of Swirltex’s technology. Given a coal wastewater sample, Swirltex identified four main contaminants:

- Fecal Coliforms

- Total Suspended Solids (TSS)

- Total Kjeldahl Nitrogen (TKN)

- Total Organic Carbon (TOC)

Without careful management, these contaminants cause serious environmental damage. Excess nitrogen causes rapid and excessive plant growth thus suppressing the growth of other, slower growing plant life. Similarly, excess organic carbon accelerates bacteria growth which disrupts the surrounding ecosystem. Furthermore, fecal coliforms indicate manure is present in water which can cause serious illness.

Cleaning Coal Wastewater

For this project, Swirltex focused on removal efficiency. Our team conducted a flux performance comparison to gauge the effectiveness of the Swirltex system versus standard ultrafiltration practices.

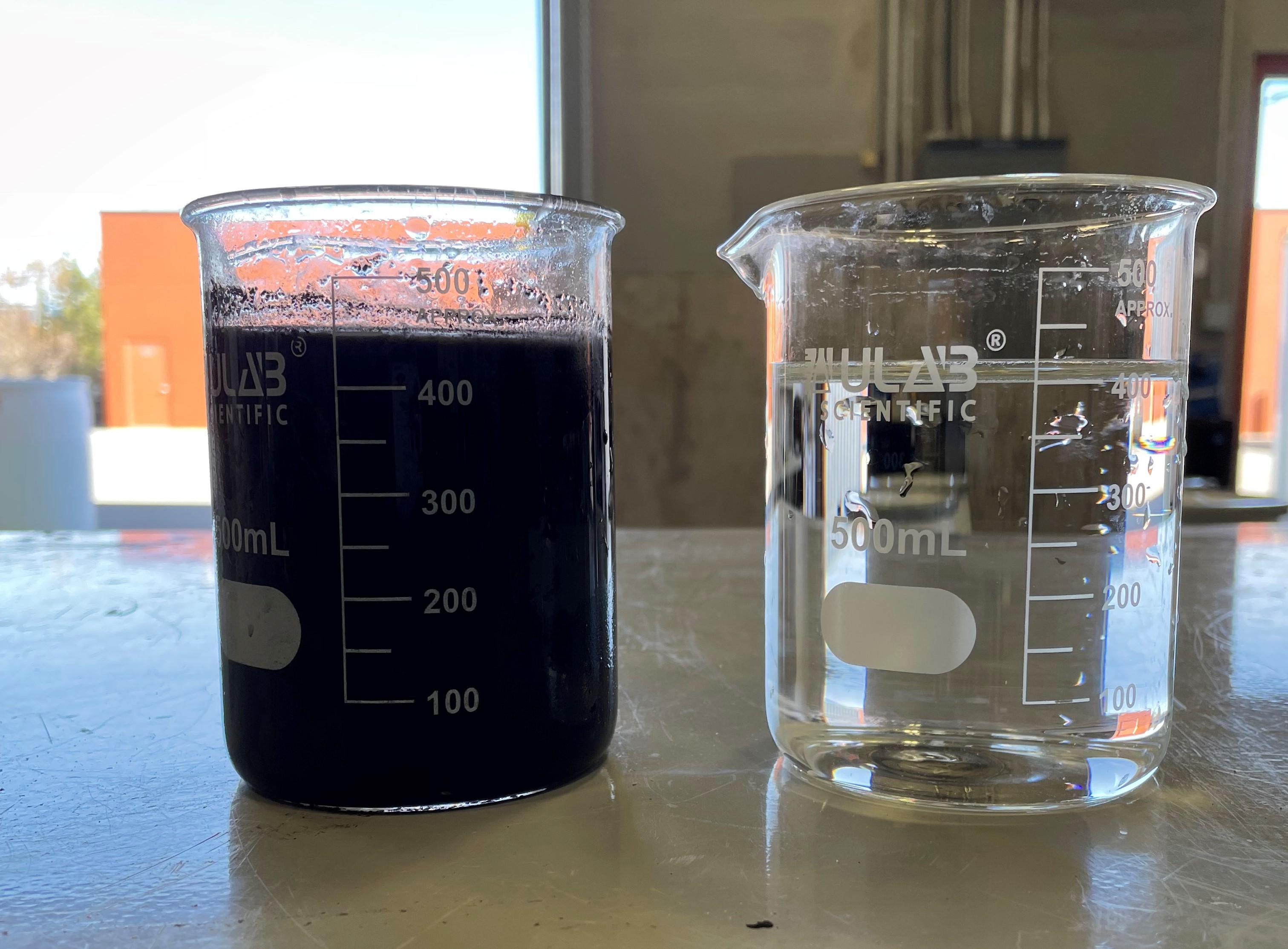

As shown, Swirltex’s technology produced excellent results. All contaminant categories saw at least 98% reduction which exceeds industry standards for contaminant removal. Compared to the standard 3 m/s flux velocity, Swirltex’s system used 1 m/s flux velocity while achieving a 240% increase in permeate production. As such, the Swirltex system outperformed standard systems with minimal energy consumption. Our system delivered superior results while achieving higher flux and stabilizing faster than competing ultrafiltration systems.

The advantages of Swirltex’s membranes go beyond filtration itself. After cleaning, Swirltex membranes recovered 93% of their initial performance versus the 6% performance recovery of the non-Swirltex system. Swirltex’s exceptionally performance recovery is possible because of the system’s unique flow-pattern. Annular flow is induced within each tubular membrane as the wastewater enters the system. The vortex of water keeps the contaminants in the center of the tube while clean, treated water exits through the membrane walls. This ensures that contaminants have minimal contact with the membrane itself, preventing irreversible damage to the membrane walls.

Swirltex Solution – The Finest Solution

Swirltex’s ultrafiltration system easily removes the finest particles from coal wastewater, consistently producing high-quality permeate. In terms of removal efficiency, energy consumption, and ease of maintenance, Swirltex’s ultrafiltration is superior to its competition. Our buoyancy-enhanced membranes separates solids and liquids for greater permeate production and higher quality effluent. Our clean technology facilitates water re-use to help reduce the strain on global and local water supply. Swirltex provides exceptional removal efficiency without the maintenance costs of conventional filtration systems. Our patented technology treats challenging wastewater streams at higher throughput, lower energy consumption, and in a broader range of climates. Swirltex’s technology meets or exceeds performance expectations and regulatory standards. Simply put, we succeed in the toughest applications where others cannot. Swirltex is the future of filtration with systems that are efficient, effective, and designed to deliver superior results again and again.