Products

Swirltex membrane treatment skids leverage Direct Crossflow Filtration (DCF) to deliver high-throughput, low-fouling wastewater treatment in a compact, modular platform. By using air to manipulate contaminant buoyancy and inducing controlled swirl within the membrane tube, DCF draws contaminants away from the membrane surface—significantly reducing the conditions that drive fouling while sustaining high performance. In typical applications, Swirltex systems achieve an average 63% reduction in energy use, an average 124% increase in flux, and an average 72% decrease in membrane fouling, translating into a lower environmental footprint, lower $/m³ treated, higher uptime, and reduced maintenance burden.

To match a wide range of wastewater streams and site constraints, our skids are offered in three membrane size configurations, allowing customers to right-size capacity without changing platforms. The lineup scales seamlessly from 200 m³/day to 2,000 m³/day, supporting everything from pilot deployments to full-scale plant integration with the same core technology and operating approach.

SX-4

The SX-4 is our most compact DCF membrane skid, built around a 4-inch membrane tube for high-performance treatment in a smaller footprint. It is ideal for pilots, early-stage deployments, and lower-flow wastewater streams where space, mobility, and fast installation are priorities—while still delivering the high-flux, low-fouling benefits of Swirltex DCF.

SX-10

The SX-10 is the mid-capacity workhorse in the Swirltex skid lineup, featuring a 10-inch membrane tube to balance throughput and footprint. Designed for variable, real-world wastewater conditions, it provides robust day-to-day performance for commercial operations and scale-up projects—maintaining strong flux and reduced fouling to drive lower $/m³ treated.

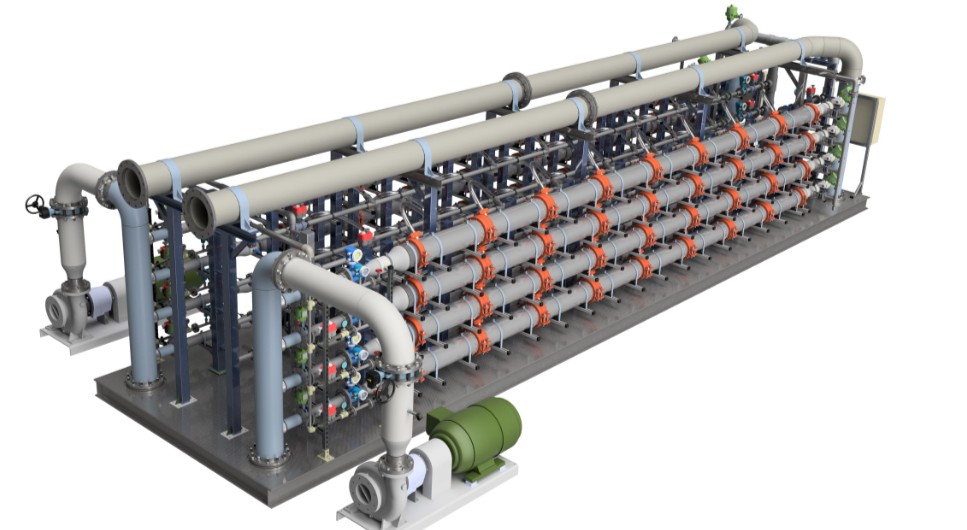

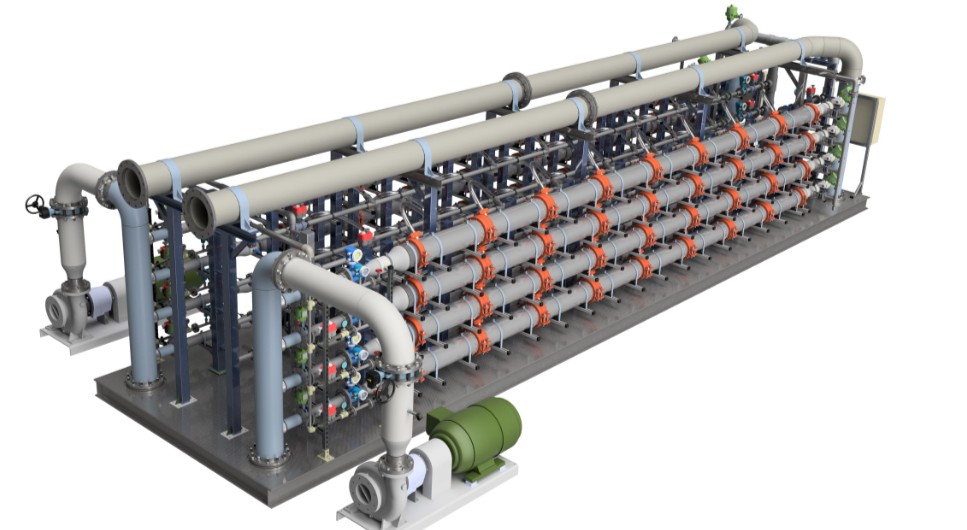

SX-12

The SX-12 is our highest-capacity configuration, built on a 12-inch membrane tube to maximize flow handling and operational efficiency at larger sites. It is engineered for full-plant integration and higher-volume wastewater streams, delivering strong process resilience, high uptime, and reduced maintenance intensity—while preserving the core energy and fouling advantages of Swirltex DCF.