Produced Water Treatment Conference Features Swirltex President

30 May 2022

Wastewater Treatment – The Swirltex Story

28 June 2022Industrial Water Treatment Meets Sustainability at Swirltex

With new developments arising in the economy, the industrial water treatment industry has also been developing tremendously. The oil and gas industry consumes a lot of water resources, resulting in the production of high levels of wastewater. Attention to water after its usage (i.e. wastewater) is often an overlooked part of the water management cycle. Therefore, this negligence can have highly detrimental impacts on the sustainability of water supplies, human health, the economy, and the environment.

Industrial Water Treatment

Industrial water treatment is applicable to processes-like fracking or mining-where water recycling would be inefficient to treat. It carries heavy metals, dirt and gravel, concrete, oil, and solvents that are difficult to filter out. This wastewater can be toxic, corrosive, ignitable, or reactive, making it unsuitable for agriculture, recreation, or further industrial use. Industrial water treatment is not only difficult to handle but, because it cannot be reused, so industrial companies rely on clean water to continue operations. This is an issue because straining our limited supply of clean water means inevitable water scarcity. The UN reports that, by 2025, two-thirds of the world’s population will face water stress whether it is physical scarcity or economic scarcity of water.

Produced Water

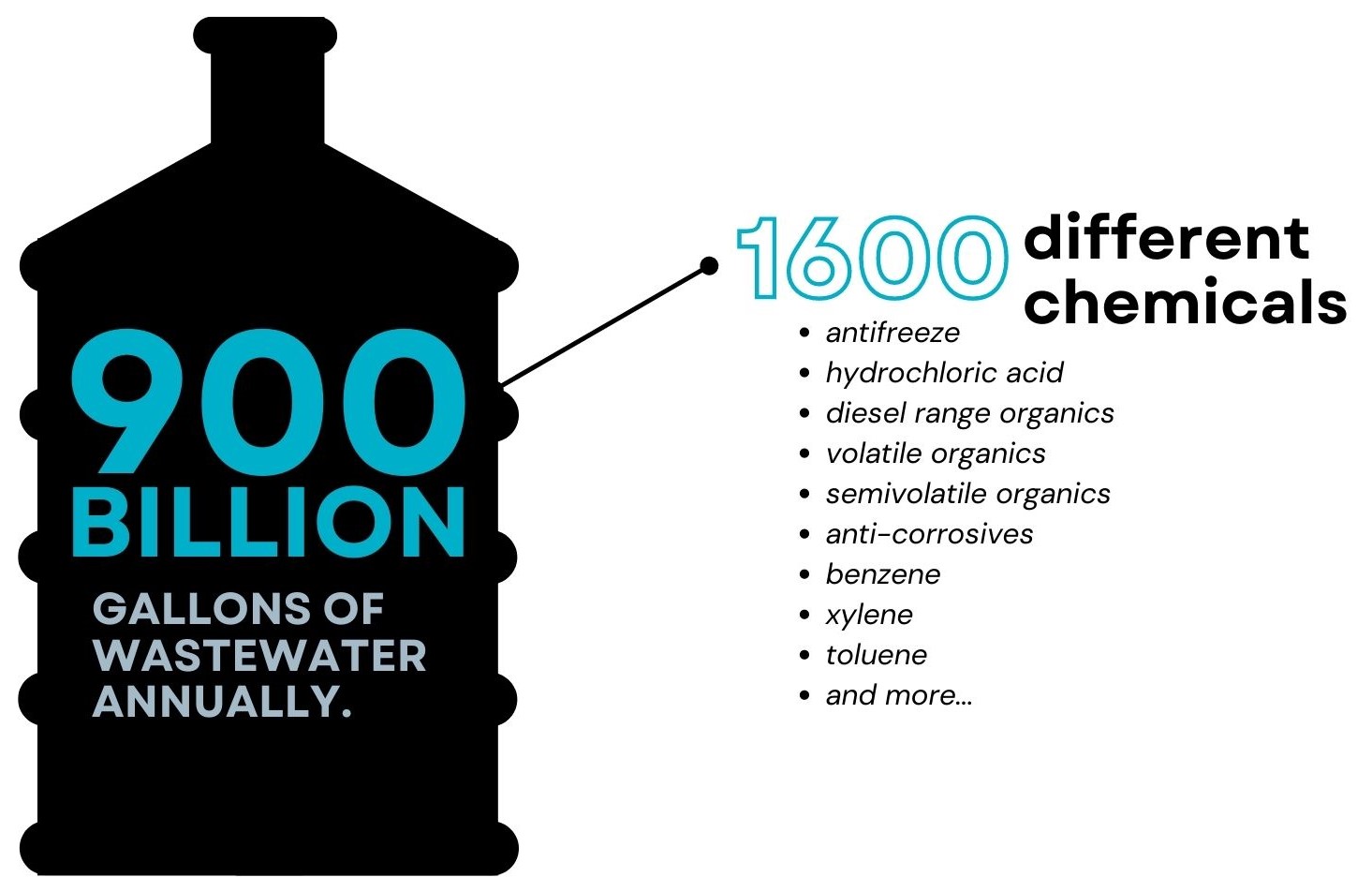

The oil and gas industry production and operations generate high levels of wastewater (also known as produced water). The cost concerns, the need to conserve water, and produce high quality permeate are major concerns for energy companies. Some wells in the United States, are predicted to be producing up to 10 times more wastewater than oil. Some companies are producing nearly as high as 900 billion gallons of wastewater annually. Produced water can ruin soil for generations if it spills or leaks in storage or transportation. The spill can contain any number of nearly 1,600 chemicals that are known to be used in industrial processes. Chemicals ranging from ethylene glycol (antifreeze) to hydrochloric acid are often dealt with in industrial water treatment.

Produced water is typically disposed of in deep injection wells or put in storage. However, facilities struggle to scale operations to treat produced water appropriately. It is a constant challenge to eliminate oil and grease, solids, or high levels of nitrate or phosphate. Without recycling water after its original use, we overlook an incredible opportunity to become more sustainable. At Swirltex, it is our mission to transform this liability into a resource.

The Swirltex Solution

Clean water is critical for social development and a prerequisite for sustainable economic development. Industrial water treatment is a complex, expensive process with significant environmental impact. Swirltex’s buoyancy-enhanced membrane separates solids and liquids for greater permeate production and higher quality effluent. We succeed in applications where conventional systems fail. Swirltex’s patented technology treats challenging wastewater streams at higher throughput, lower energy consumption, and in a broader range of climates. Our ultra-filtration allows produced water to be reused or disposed by effectively removing iron, solids, oil, and more. The Swirltex system improves removal efficiency without the costly, long-term operational issues associated with conventional filtration systems.