Direct Crossflow Filtration

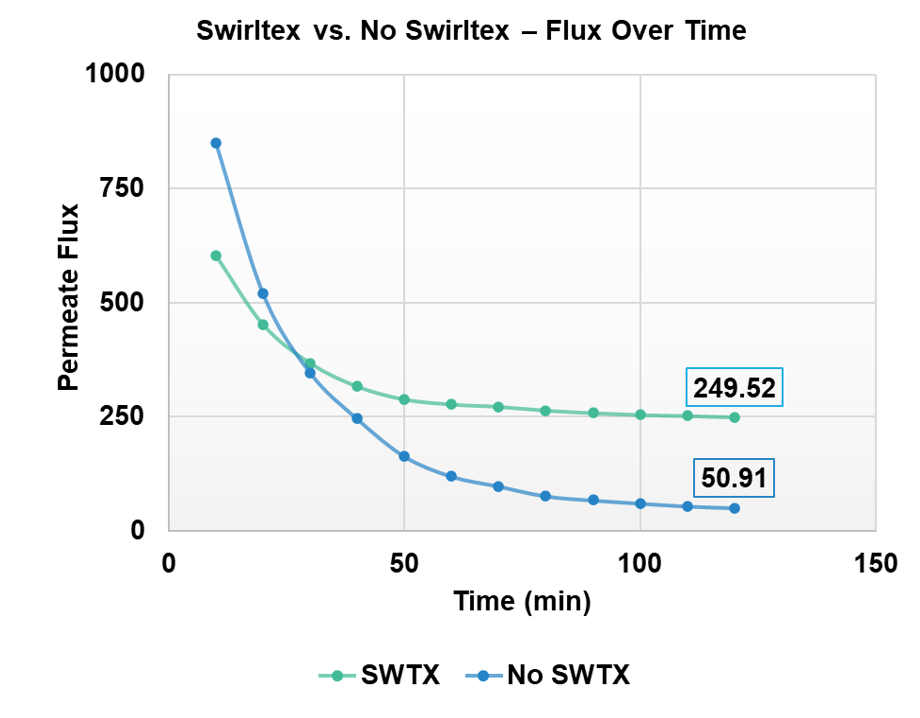

Swirltex’s Direct Crossflow Filtration technology significantly reduces energy consumption, membrane fouling, scaling issues and long-term OPEX costs in challenging and impossible wastewater treatment applications. By implementing hydraulic manipulations, this process also enables the conventional polymeric tubular membranes to operate at 3x–6x the flux rates of a traditional process design, thus reducing equipment size requirements for most applications.

SWIRLTEX TECHNOLOGY IS THE EVOLUTION OF MEMBRANE ULTRAFILTRATION:

Conventional membrane-based wastewater treatment processes suffer from drawbacks such as high energy consumption, fouling, and maintenance costs, making them inefficient and expensive to operate. Swirltex uses off-the-shelf membranes in a novel way, enabling them to be used in complex wastewater applications and facilitating water reuse. Swirltex’s unique membrane system separates solids and liquids based on “buoyancy”, allowing for higher flux production rates and quality permeate.

HOW direct crossflow FILTRATION WORKS:

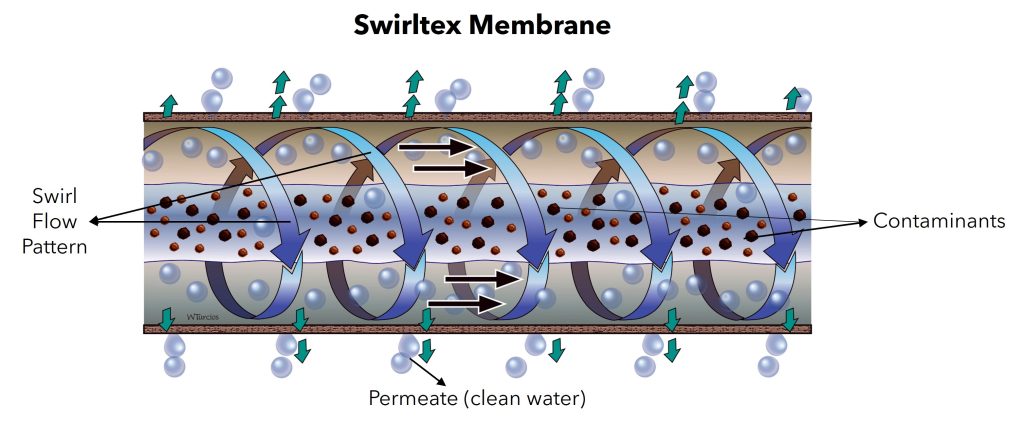

The Direct Crossflow Filtration process achieves its benefits through a two-step hydraulic manipulation of wastewater. First, air is injected into the waste stream. The air forms bubbles and the oils, solids, and other contaminants attach themselves to the bubbles.

Second, a swirl flow pattern generated in the membrane induces buoyancy-based separation of water and contaminants. This leads to the annular flow along the entire membrane length, with contaminants and gas concentrated at the center of the membrane tubes.

Annular Flow Demo

Direct Crossflow filtration TECHNOLOGY FEATURES:

- Annular flow design enhances cross flow efficiency resulting to reduced membrane fouling and higher permeate flux.

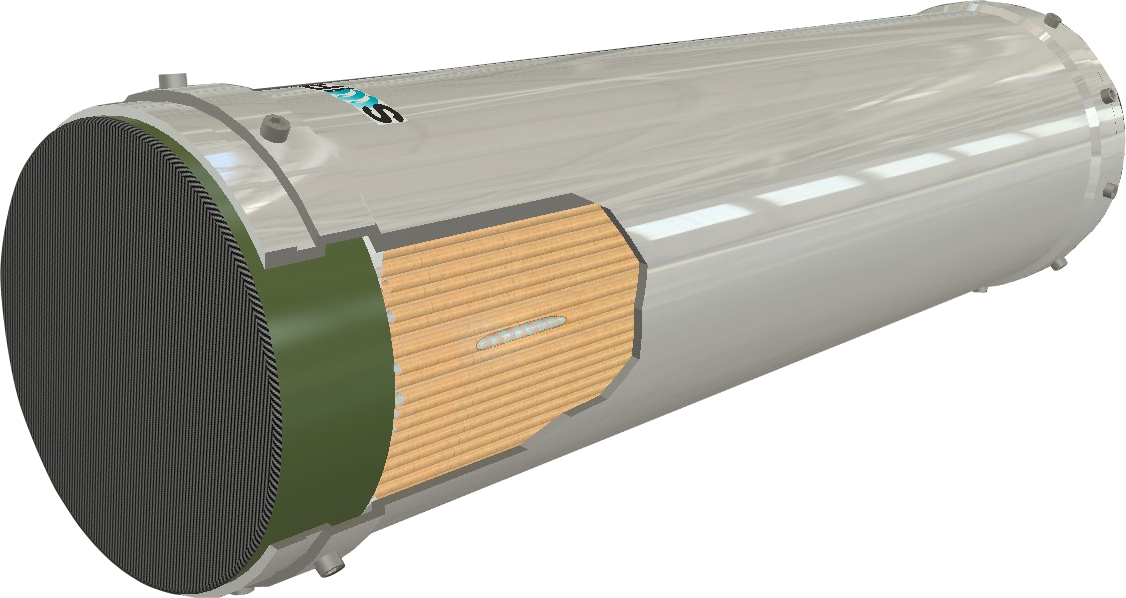

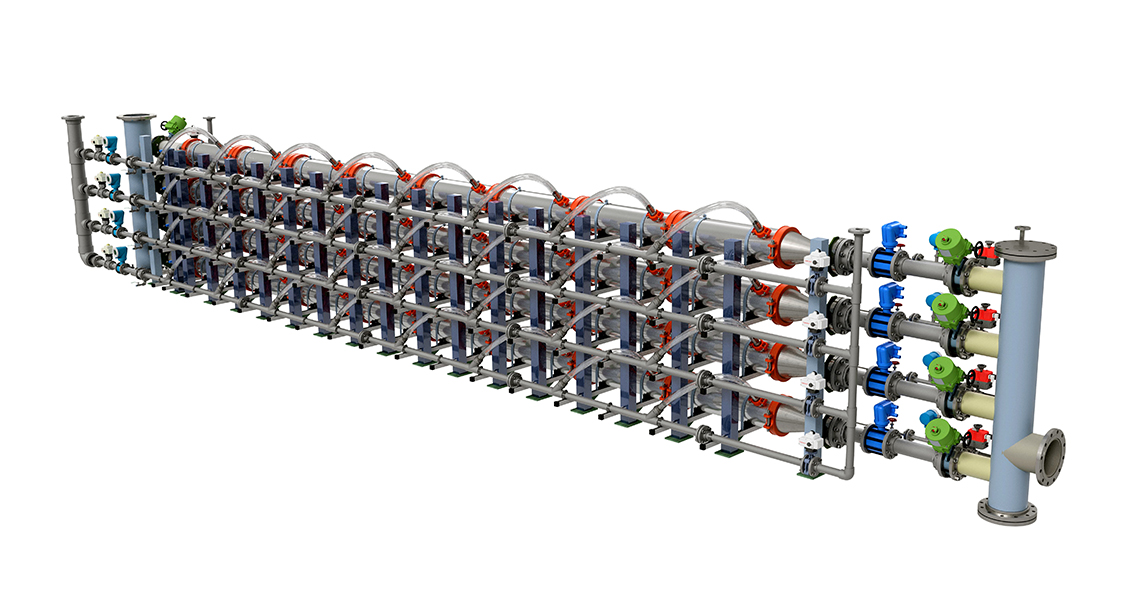

- Easy to handle 1-meter long membranes with diameters of up to 8 metres depending on influent water quality.

- Biologically friendly clean-in-place systems with no downtime.

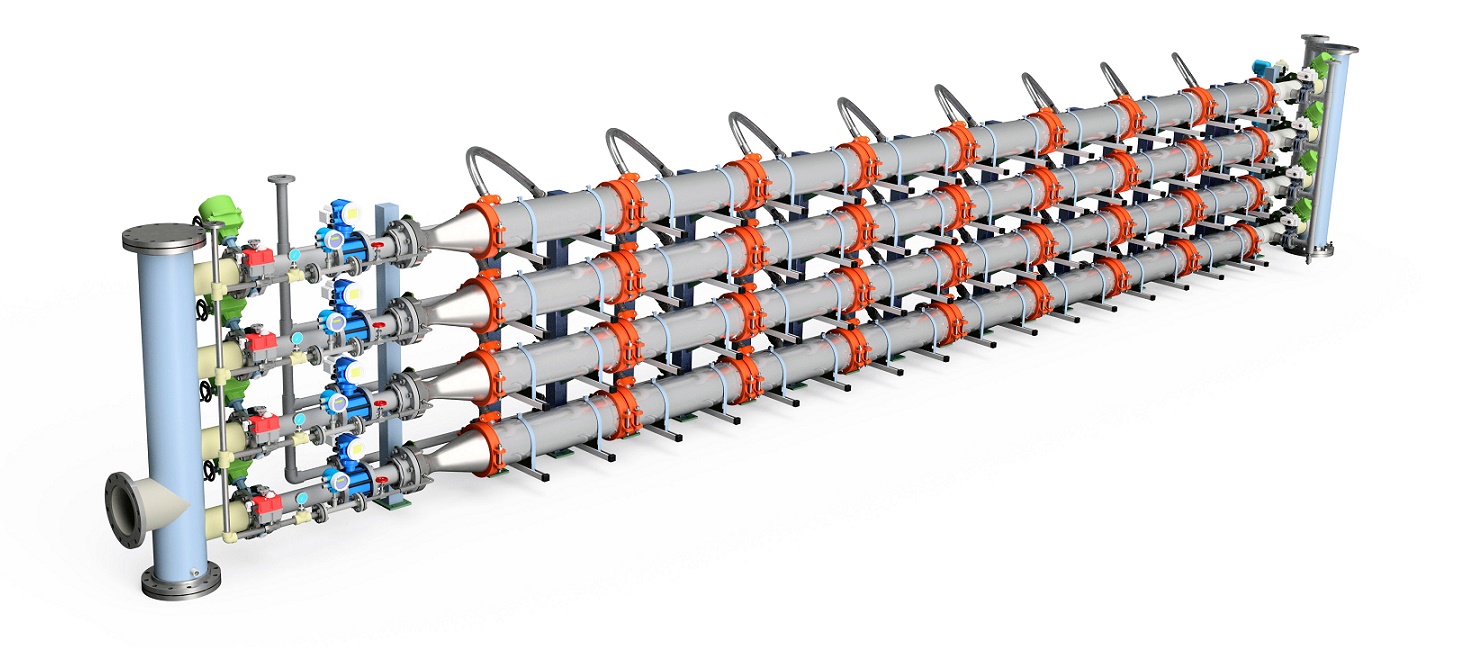

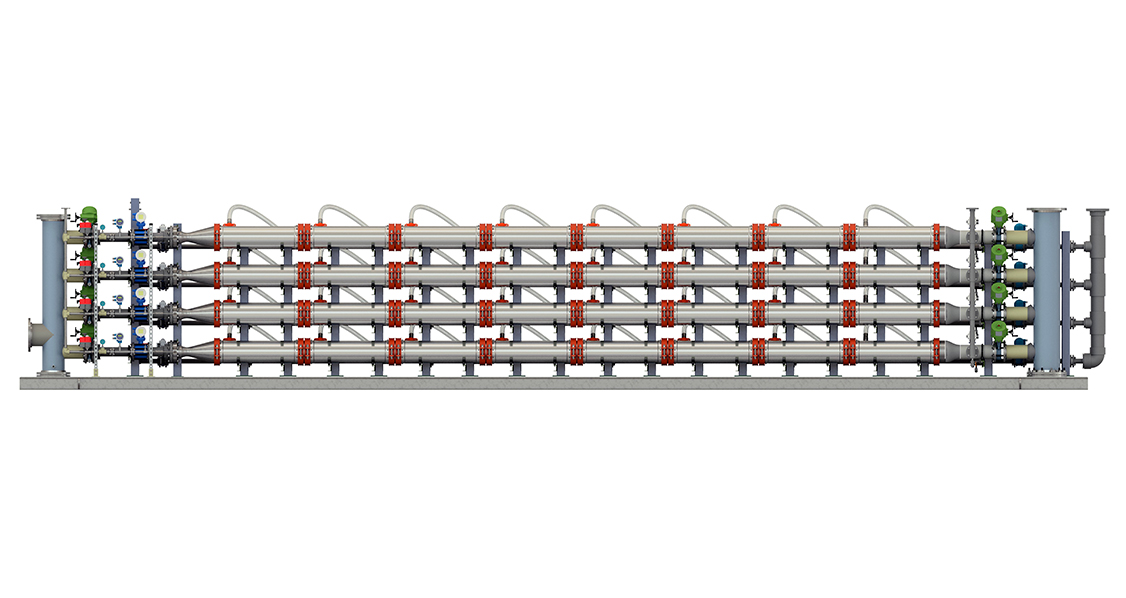

- Variable flow: each membrane bank can be operated individually.

- Highly effective process for water/solids separation, TSS & Oil & Grease

1-meter Long Swirltex Membrane

PROVEN BENEFITS OF direct crossflow FILTRATION

COMPARATIVE DIFFERENCE BETWEEN SWIRLTEX TUBULAR MEMBRANES VS OTHER MEMBRANES

- Low power consumption

- High quality treated water suitable for reuse

- Allows for remote monitoring of operational flux via ethernet or Wi-Fi.

- Easy operations and maintenance thereby Increasing operational life of system

- Ability to treat different wastewater types and flow rates up to 10 – 10,000m3/day

- Compact with a small footprint for ease of transport or flexibility